Fixturing and Routing of Plastics with CNC - LMT Onsrud Can Be Fun For Everyone

How Get Machined Plastic Prototypes - CNC Manufacturing can Save You Time, Stress, and Money.

Disadvantages, Pure polycarbonate does not have good wear resistance and is prone to scratches. Anti-scratch coverings and vapor polishing can be included as a post processing action to improve wear resistance or optical clarity, if required. It is also not easily offered in pieces over two inches thick, which restricts the size of parts that can be made from polycarbonate.

Main Takeaways, Hopefully, this guide has provided insight into which plastic is best suited to your application. To find out more on extra CNC products and CNC machining services in general, see Fictiv's site.

How Plastic CNC Machining Has Transformed the Medical Industry: 2021

CNC Plastic Machining Services - CNC Plastic Milling - Miller Plastic

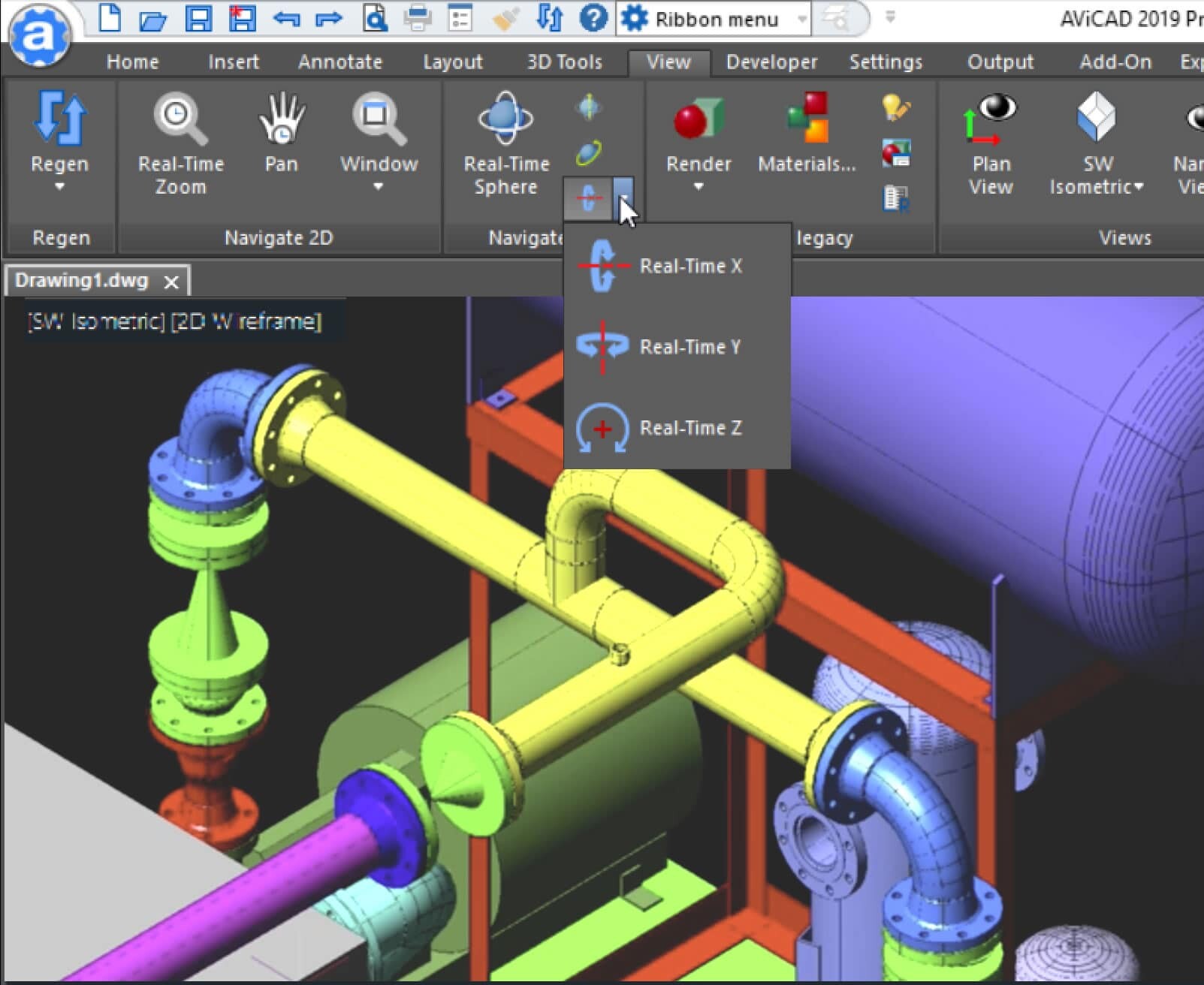

What is CNC Plastic Machining? In order to understand the breadth of experience Jaco has in CNC plastic machining, it's important to likewise understand what "CNC" implies. CNC means computer system mathematical control, and is a machining process in which a pre-programmed computer software feeds directions to tools and equipment to create products.

The Definitive Guide for CNC MACHINING - House of Plastics Unlimited Orlando, FL

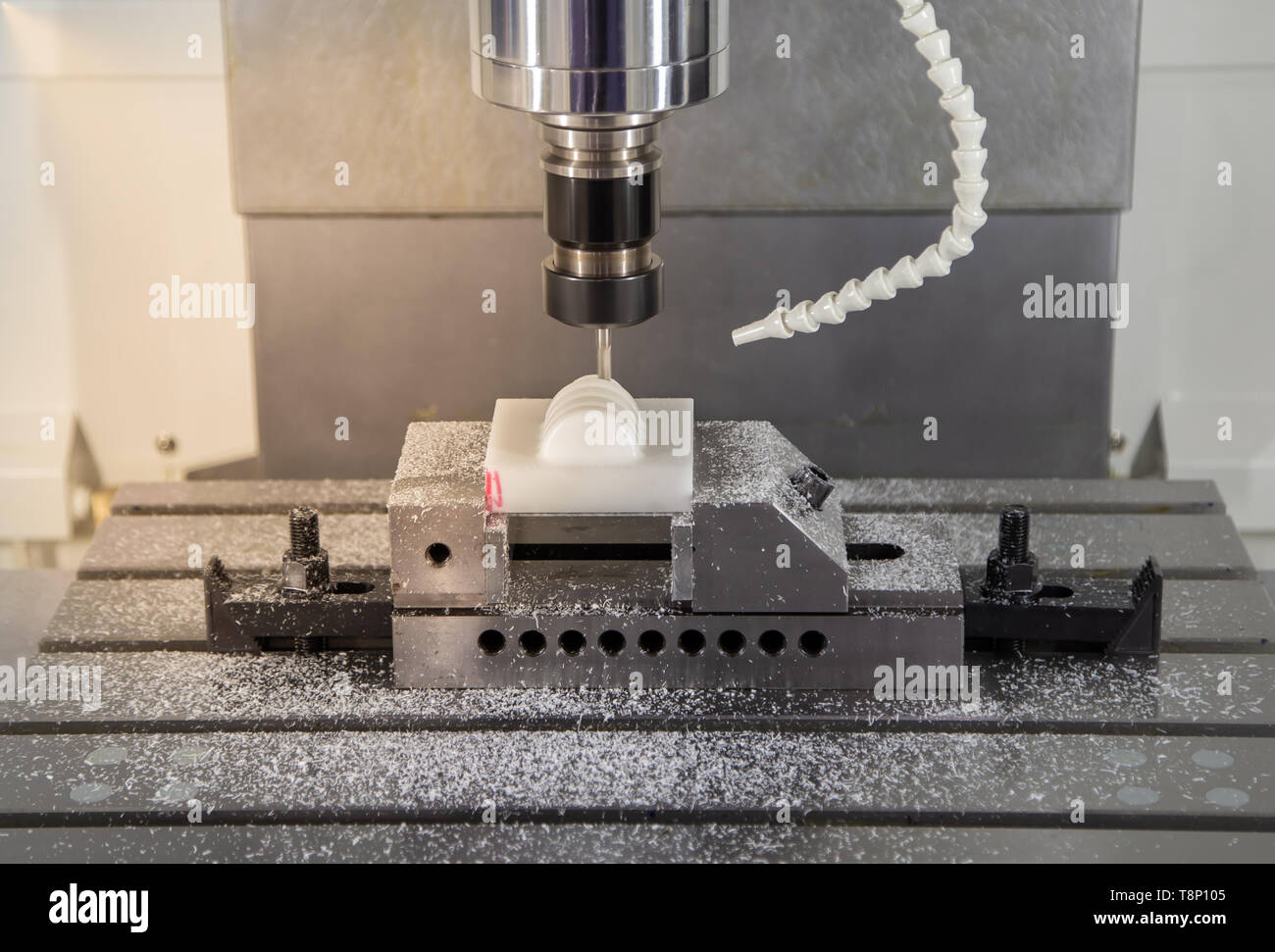

CNC devices can control grinders, lathes, mills, and more. Another benefit of CNC plastic machining is that it can permit three dimensional cutting tasks to be done in a single set of prompts. Because of Source , it's preferred for more intricate parts. Manual machining needs that an operator be there to assist the machine(s) using levers and buttons.

This innovative approach merely requires the best directions to feed to a maker, and it can finish jobs instantly. CNC Plastic Machining Types As mentioned, CNC maker for plastic productions can utilize a variety of various tools and operations. Whether you require to complete PEEK CNC machining or a various kind of CNC plastic procedure, here are some makers that might be used.

Utilizing CNC plastic machining, the lathes perform the cutting with accuracy and high velocity. When compared to manual makers, CNC plastic operations can produce even more complicated designs that just aren't possible without this sophisticated innovation. A plasma cutter works by utilizing a plasma torch to cut product. Instead of CNC maker for plastic productions, the plasma cutter is frequently used in metal processing.

Your Ultimate Guide to Plastic CNC Machining - The Silicon for Dummies

The most fundamental CNC mills use a three-axis system (X, Y, Z) to form parts. Nevertheless, more sophisticated CNC plastic technology can sometimes incorporate as much as 3 extra axes. Plastic CNC Machining Parts Although CNC machining can be utilized for a variety of products, Jaco Products focuses on working with a variety of plastics.